Success story

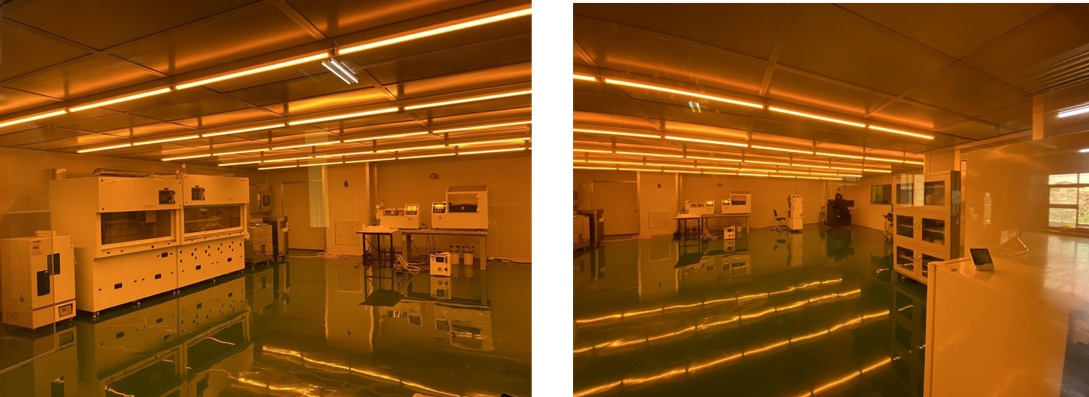

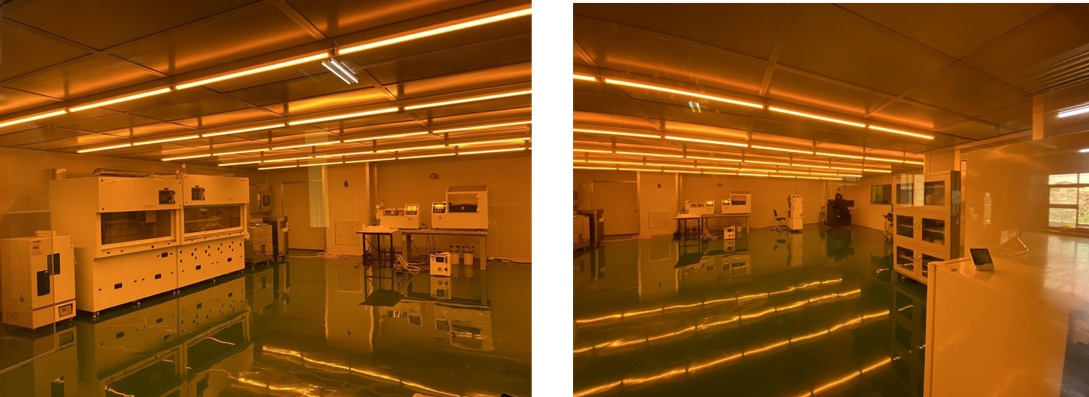

1. Class 1000 Clean Room

2. Class 10,000 Clean Room

3. Class 100,00 Clean Room

4. Class 100,00 Clean Room

5. Clean Room Design considering point.

1). In terms of environmental conditions:

(1). Whether the moving lines of personnel, materials, and manufacturing equipment are appropriate.

(2). Are there areas with different cleanliness levels, such as the process area, maintenance area, and aisle area make a clear distinction?

(3). Whether the control of temperature and humidity is a 24-hour automatic monitoring control and usage mode.

(4). Whether the pipelines and moving lines of the factory supply system are smooth.

(5). Design evaluation of clean room level.

(6). The convenience of Hook-up construction. Convenience of overall system maintenance

2). In terms of economic considerations:

(1). The rationality of the factory supply system and equipment procurement.

(2). The life cycle of factory supply system and equipment operation.

(3). Initial setup cost.

(4). Operation cost.

3). In terms of reliability considerations:

(1). The stability of the factory supply system.

(2). Stability of process equipment operation.

(3). Feasibility assessment of high productivity

(4). The reliability of the raw materials used.

4). In terms of safety and environmental protection considerations:

(1). The safety considerations for workers in the clean room, such as whether the evacuation route direction is clearly marked.

(2). Classification control and prevention of noise, vibration, acid discharge, drainage, exhaust, etc.

(3). Location configuration icon display and hanging.

(4). The establishment of fire-fighting equipment such as smoke exhaust and water sprinkling to detect smoke.

(5). Emergency lighting, flushing and eyewash installation design.

(6). Establishment of monitoring system for poisonous gas, waste gas and waste water.

(7). An emergency network is established when an accident occurs.

(8). Establishment and implementation